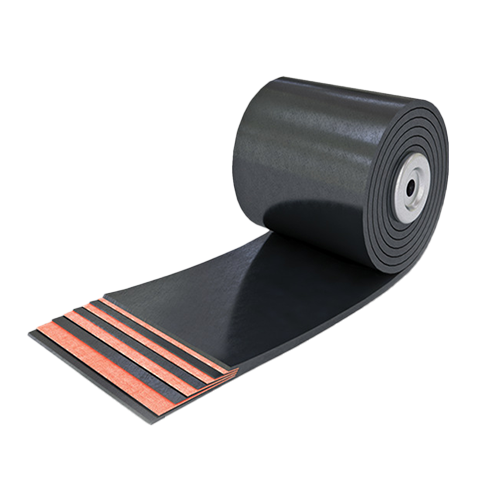

Product Types

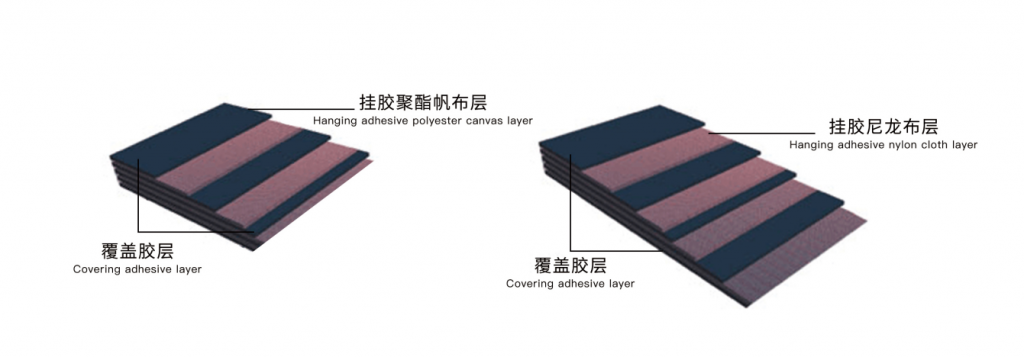

Based on the properties of the fabric core and cover rubber, fabric conveyor belts can be classified into several types:

·General Fabric Conveyor Belt

Suitable for material transport under normal temperature and dry conditions.

·Heat-Resistant Fabric Conveyor Belt

Designed for transporting high-temperature materials like hot coke, ore powder, and cement clinker.

·Cold-Resistant Fabric Conveyor Belt

Ideal for low-temperature environments to prevent brittleness.

·Oil-Resistant Fabric Conveyor Belt

Transports oil-containing materials or operates in oily environments.

·Flame-Retardant Fabric Conveyor Belt

Flame-retardant and anti-static; suitable for coal mines, metallurgy, and chemical industries.

Maintenance and Care

Note:

For more information on conveyor belt specifications, selection, or customization services, please contact our sales team.

Product Features

Need a custom solution?

Let’s make it simple.

Professional OEM/ODM services to match. From function to design, we offer fast and flexible customization to meet your exact needs.

Customization Options

Applications Across Industries

Reach Out Today

Contact us to get a free quote, your project will meet a right solution with us.