Maintenance and Care

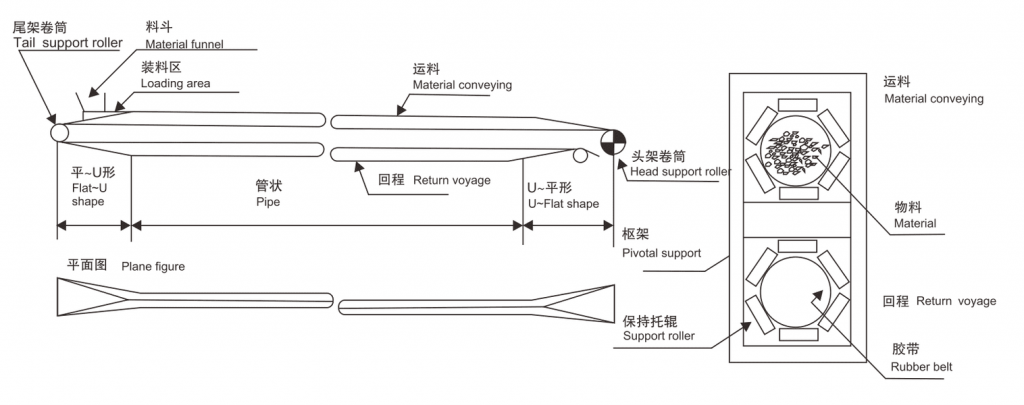

Pipe conveyor belts are widely used in bulk material handling applications across mining, power plants, cement, ports, and more. To ensure long-term reliability and performance, regular maintenance is essential. Below are key care guidelines:

1. Regular Inspection

Conduct visual inspections at least twice a day. Focus on wear, cracking, misalignment, or physical damage. System checks should also be done before and after each operation.

2. Belt Alignment Adjustment

If twisting or off-center movement occurs during operation, inspect and adjust the idler arrangement and tensioning devices to maintain proper belt tracking under all loading conditions.

3. Cleaning and Lubrication

Clean the rollers, supports, and belt surface regularly to avoid material buildup and mechanical wear. Lubricate rotating parts such as bearings and rollers at scheduled intervals.

4. Tension and Splice Check

Ensure the belt tension is within the recommended range to prevent slippage or over-stretching. Pay special attention to splices for signs of tearing, delamination, or failure.

5. Storage and Spare Management

Store spare belts vertically in a dry, ventilated area, away from direct sunlight and moisture. Rotate stored belt rolls periodically to prevent deformation.

6. Safety Training

Operators should receive professional training to understand system design and correct operation practices, minimizing risks of accidents and extending service life.

Note:

For more information on conveyor belt specifications, selection, or customization services, please contact our sales team.

Product Features

Need a custom solution?

Let’s make it simple.

Professional OEM/ODM services to match. From function to design, we offer fast and flexible customization to meet your exact needs.

Customization Options

Applications Across Industries

Reach Out Today

Contact us to get a free quote, your project will meet a right solution with us.