How Oil Resistant Rubber Belting Helps the Farmers During the Winter Harvest Season?

How Oil Resistant Rubber Belting Helps the Farmers During the Winter Harvest Season?

Is your farm ready for the winter harvest? Are you still relying on manual labor? What if we say you can enhance your farm’s operations with rubber belting?

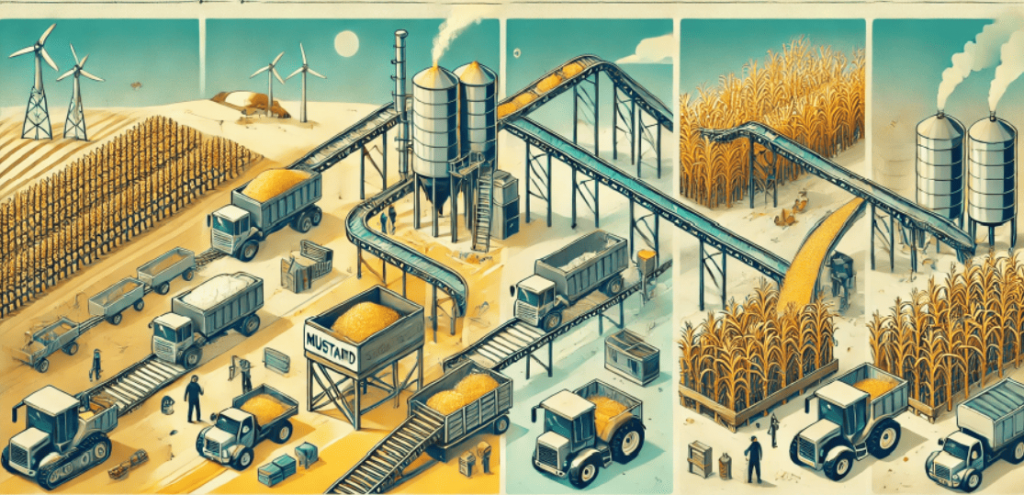

The harvest season is the most critical time for the farmers. Even if your year’s produce is satisfactory, timely harvesting them is necessary to enjoy good profits. Although many farmers still do not prefer to trust modern equipment like a rubber conveyor belt on their farm- change becomes inevitable sometimes.

Rubber belt conveyor works on automated systems. They are used to transport bulk materials from one place to another- no matter the distance.

However, you cannot use just any type of rubber belt conveyor when it comes to transporting food grains, nuts, seed kernels, etc. Do you know why?

Which rubber conveyor belt material is fit for farm use then?

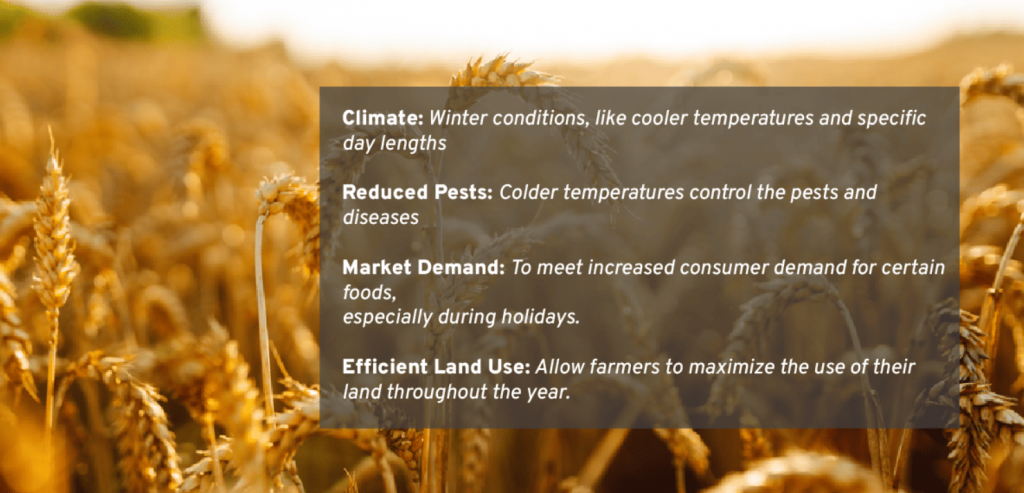

Why Are Some Crops Harvested in Winter?

The winter marks the occurrence of a lot of Indian harvest festivals- Lohri, Makar Sankranti, and Bihu. On the other hand, globally, we have various winter/autumn harvest festivals like the Sukkot and Thanksgiving, as well.

Now, why are crops harvested during this time when the weather is so harsh?

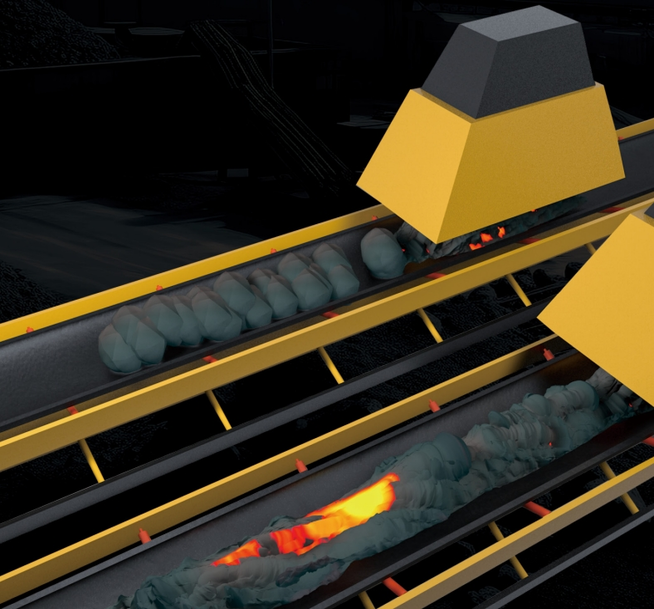

Winter Harvest: Rubber Belting Contributes to Resilience in Cold and Greasy Conditions

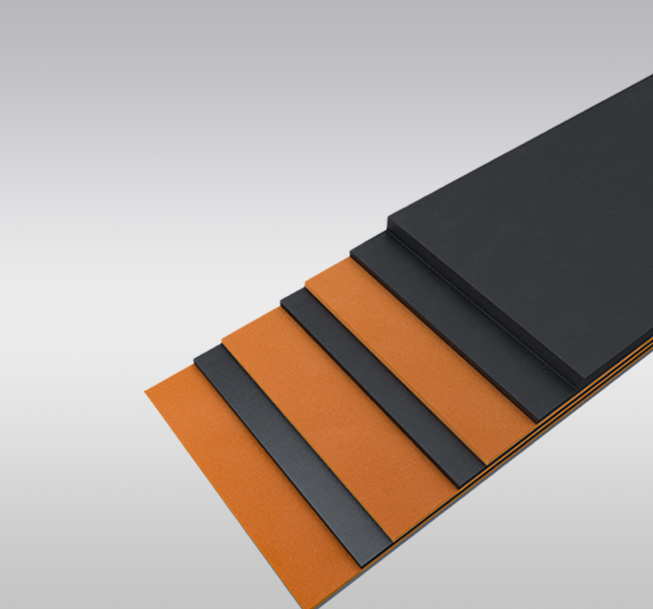

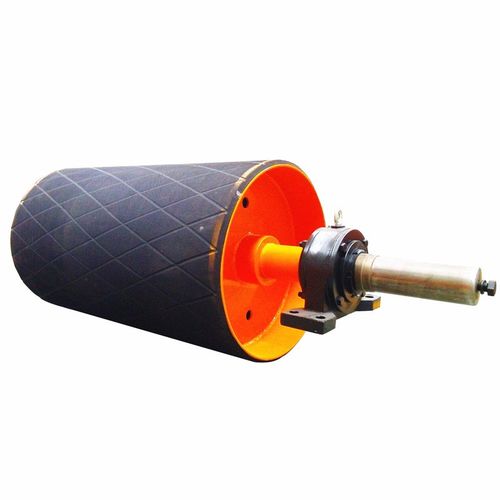

Wheat, Barley, Mustard, and Rapeseed are mainly harvested among the other winter or Rabi crops. However, the weather is cold and wet outside. If you take too much time harvesting them, it will damage the crops. Nevertheless, belt conveyor rubber makes the process first. The synchronization of rubber belting, conveyor pulleys, motors, and other parts of a conveyor system can transport bulk material in less time than labor.

Early Spring: Rubber Belt Conveyor For Added Efficiency

Crops are not usually harvested during early spring. However, this is the time when farmers prepare for the busy harvest season once again in the late summer. Investing some time now to maintain rubber conveyor belting saves farmers both time and money.

Oil Resistant Rubber Belting to the Rescue: Why Cannot You Use Anything Else?

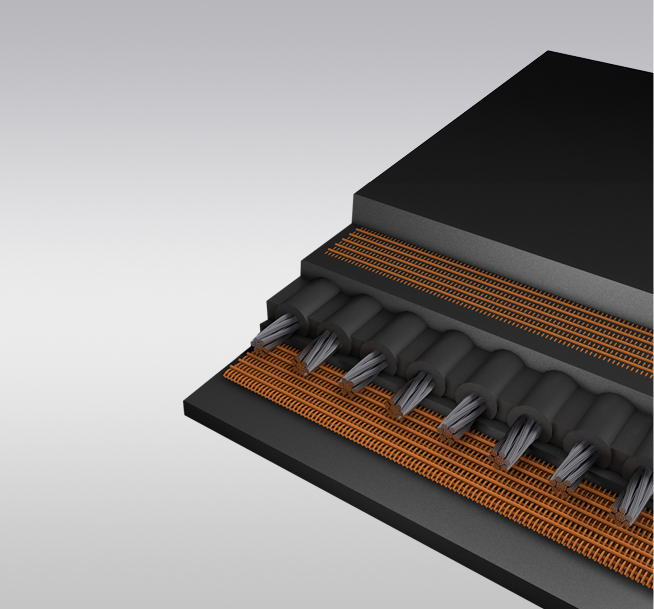

Belt conveyor rubber comes in different variants. According to rubber belting suppliers, there are:

·Abrasion-resistant rubber belting

·FR-grade or fire-resistant rubber belting

·HR-grade or heat-resistant rubber belting

·OR-grade or oil-resistant rubber belting

What is Oil-Resistant Rubber Conveyor Belt Material?

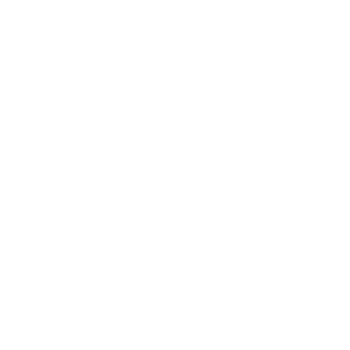

Oil-resistant rubber conveyor belting is made of high-quality rubber that can withstand oil, grease, and fat. Typically, rubber degrades when it comes in contact with oil or grease. The rubber can absorb the oil or grease, causing it to expand in size, leading to changes in shape. Additionally, oil or grease can soften the rubber, making it less rigid and more prone to deformation or tearing. Therefore, if you use an abrasion resistant rubber conveyor belt or a fire-grade rubber belt conveyor, it will ultimately be of no use; additionally, it will require and lead to:

·More Replacements: You cannot use swollen belt conveyor rubber and will need more replacements.

·Financial Loss: Evidently, you will have to spend more when there are frequent replacements and repairs of the rubber belting.

·Production Downtime: You cannot work with faulty systems causing production downtime.

Benefits of Using An Oil Resistant Rubber Belting

While other types of belt conveyor rubber might not be suitable for your farm’s operations, an oil-resistant rubber belting brings you these benefits:

Resistance to Oils and Grease: Prevents swelling, cracking, or degradation caused by exposure to crop oils, lubricants, and greasy residues.

Durability in Extreme Conditions: Some variants, like a 6 ply rubber belt, are tough and perform efficiently in cold winters and high-stress environments, ensuring reliability across seasons.

Improved Machinery Efficiency: A combination of equipment like harvesters and conveyors reduces slippage and breakdowns, enabling smooth operation.

High Load-Bearing Capacity: An OR-grade rubber belting handles bulky crops like sugarcane and rice without mechanical wear or reduced grip.

Versatility: According to rubber belting suppliers, a rubber belt conveyor is suitable for various agricultural applications, including harvesting, transportation, and post-harvest processing.

Cost-Effectiveness: High-quality rubber conveyor belt material reduces downtime, operational costs, and long-term investment in replacement parts.

Enhanced Productivity: Ensures uninterrupted harvesting and transportation, saving valuable time during tight harvest schedules.

Related Products

Professional OEM/ODM Services to Match Your Needs

We offer fast and flexible customization to meet your exact needs.

Reach Out Today

Contact us to get a free quote, your project will meet a right solution with us.

Tell Us What You Need

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea to us.

Get Solution & Quote

We will work on the best solution according to your requirements, and quote will be provided within 24 hours.

Approve Mass Production

We will start mass production after approval and deposit, and we will handle the shipment and future after-sale service.